Nanotechnology

uses phenomena and structures that occur on the scale of small atoms and molecules

— a DNA helix, for example, is 2 nanometers in diameter — to make

an array of tiny tools. Early forms of nanotechnology already pervade the modern

world, in everything from paint pigments to biomedical devices.

Nanotechnology

uses phenomena and structures that occur on the scale of small atoms and molecules

— a DNA helix, for example, is 2 nanometers in diameter — to make

an array of tiny tools. Early forms of nanotechnology already pervade the modern

world, in everything from paint pigments to biomedical devices. Future strategies for solar energy should follow on principles in nature, where energy is stored in chemical bonds. Some promising research into this artificial photosynthesis focuses on nanotechnology for semiconductors — essentially altering solar energy cells on the molecular scale. Image is courtesy of Corbis.

On the distant horizon is molecular nanotechnology, literally the organization

of matter at molecular scales. Imagine, for example, “smart” clothing,

in which the molecules comprising the fabric can change in response to weather.

The idea, as sketched by the late Richard Feynman at a meeting of the American

Physical Society at Caltech in 1959 and elaborated on later by many others,

is to enable the manipulation of individual atoms and molecules, using proportionally

smaller tools to build and operate even smaller tools.

Biological systems are the perfect models for molecular nanotechnology, inspiring

future nanotechnology. The capabilities of biological systems put present technology

to shame.

Although nanotechnology is often relegated to the field of materials science,

by taking a closer look at biological systems, it could one day have a profound

effect on the earth sciences. In particular, millennia-old notions of what a

“resource” is, and the collection and use of energy, are both likely

to change beyond recognition.

Fuel

laws

Current technology squanders energy because most of it is used as heat. Indeed,

we could speak of the “heat” crisis rather than the “energy”

crisis. Fuels, after all, are burned! Two-thirds of gas in an automobile’s

tank, for example, goes right out the radiator. Due to the Carnot limit, a law

that stems directly from fundamental constraints imposed by thermodynamics,

even the most efficient heat engines waste at least half the applied energy.

Because electric batteries and motors are not heat engines, they are not subject

to the Carnot limit, making them much more efficient. Conventional batteries,

however, have other engineering issues such as low energy density and slow recharge

times. Instead, fuel cells are a promising alternative.

While similar to a battery, fuel cells allow for continuous replenishment of

the reactants consumed — producing electricity from an external supply

of fuel and oxygen as opposed to relying on the limited energy storage capacity

of a battery. And contrary to popular belief, fuel cells do not necessarily

require hydrogen.

Practical fuel cells using, say, hydrocarbons or alcohols lie beyond present

technological capabilities, as converting the chemical energy of fuels directly

into electricity requires a highly controlled molecular-scale reaction. This

process requires catalysts that are both extremely specific and robust, and

hence well structured at the nanoscale. Better catalysts in general are an obvious

application of near-term nanotechnology, and will have further profound and

ramifying effects on energy efficiency.

Another near-term nanotechnology solution involves solar energy. It is often

claimed that the high energy density of conventional fuels is not reproducible

by any conceivable alternatives, at least at the scale required for modern civilization.

But the high energy density of conventional fuels is merely a brute-force solution

that is compensating for the inefficiency of burning them. Thus, it is simply

not true that solar power is incapable of powering a technological culture.

A high-tech culture is the only sort that can be run on solar power. After

all, life itself, with its extraordinary capabilities of self-organization,

synthesis and element separation, runs on solar power. That’s why it is

amusing to consider, for example, the oft-proposed use of biomass for fuel:

Burning material originally assembled, atom by atom, from diffuse sources of

both energy and materials.

Artificial photosynthesis

Why is

solar power usually thought to involve converting sunlight into electricity?

Biology doesn’t do it that way. Natural photosynthesis stores the energy

of sunlight in chemical bonds. That makes a lot more sense biologically, as

well as technologically.

The conventional disadvantages of solar power are that it is intermittent,

and difficult to transport and store. The last two disadvantages are true of

electricity, no matter how it is created. Using sunlight to make fuels, however,

would solve the intermittency problem: Fuel can accumulate whenever the sun

is shining and then be used later when needed.

Acidic drainage from mines is a pollution

problem that could one day be a potential resource, by using nanotechnology

to separate valuable minerals and dispose of contaminants. Photo is courtesy

of Stephen L. Gillett.

Artificial photosynthesis is now receiving much attention by industry and research

groups. The most promising approaches are based on semiconductors — materials

for controlling conductivity that make possible most of modern-day electronics,

including computer chips and lasers.

As in a conventional photovoltaic (solar) cell, semiconducting materials, such

as silicon, absorb solar radiation. That radiation knocks electrons loose to

create a flow of current, and each excited electron leaves behind a vacancy,

or “hole,” that acts like a single positive charge. Conventionally,

the electrons and holes are forced to drive an electric circuit before they

recombine. Instead of driving an external circuit, however, technical alterations

can make the hole and electron drive chemical reactions that store energy.

Most research has focused on “water splitting,” the production of

hydrogen gas from water, but alternative fuel generation is possible. Familiar

semiconductors, such as silicon, are too vulnerable to oxidation reactions to

be used in such photochemical applications. Work instead has focused on oxide

semiconductors, such as titanium dioxide, which remain stable indefinitely in

an oxygen-water environment. Reaction takes place at the wetted interface between

the water and semiconductor.

To be practical, however, such semiconductor surfaces will require near-molecular-scale

structuring. Because the electrons and holes can combine to form heat, nanostructuring

of the surface is necessary to ensure reasonable charge separation. At present,

“decorating” the surface with nanoparticles of a precious metal, such

as platinum, is the favored method of ensuring charge separation, but obviously

this increases both expense and complexity.

An ironic result of such technologies is that desert areas, with their year-round

sunlight, could become major fuel production centers. In particular, the nations

of the Middle East could continue exporting fuel indefinitely, albeit in competition

with other deserts throughout the world.

Pollutant v. Resource

A fundamental technical problem involves separating one kind of atom or molecule

from a background of others: pollutants from wastewater, metals from ores, salt

from seawater. Separation is basic to purification, pollution control and resource

extraction. Defining the process is a question of context: If we want what we

separated, it is a resource; otherwise it is a pollutant.

Traditionally, however, separation has been viewed as the source of a host

of different problems. In particular, researchers have seen resource extraction

not only as distinct from pollution control, but also as intrinsically energy-intensive.

In turn, its profligate energy usage is typically justified by vague appeals

to the laws of thermodynamics.

Yet, quantitatively, element separation is not intrinsically expensive. Do

not merely believe thermodynamic calculations: Bio-logical systems underscore

how woefully inefficient conventional separation processes are, as they perform

feats that put conventional resource extraction to shame.

Organisms do not carry out thermally driven phase separation. Instead, they

literally move individual atoms or molecules, using specialized mechanisms —

for example the binding of nutrient elements by specialized proteins. These

molecular-scale processes are vastly less costly energetically and allow separation

from considerably lower concentrations.

Plant

roots extract both nutrients and water at low concentrations from the ambient

soil. Vertebrate kidneys extract only certain solutes out of the blood from

a background of many other solutes. For photosynthesis, plants extract carbon

dioxide from the air, where its concentration is only about 350 parts per million,

and furthermore do so using only the diffuse and intermittent energy of sunlight.

Diatoms are particularly impressive, building shells from silica extracted at

parts-per-million levels from the ambient water.

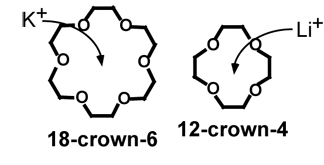

Organic compounds called “crown

ethers,” shown here schematically, could be key players in nanotechnology

designed to extract metals. The ring, or “crown,” changes in structure

by substituting differently sized atoms, such as potassium or lithium, for oxygen

in the crown. Image is courtesy of Stephen L. Gillett.

Again, the reason why conventional resource extraction is so energy expensive

is because it largely relies on vast quantities of heat, in this case to drive

the partitioning of elements into coexisting phases. Not only do such processes

require a lot of energy, but they also are intrinsically polluting, both due

to the combustion necessary to generate the heat and because the separation

is never complete. Moreover, byproducts containing geochemically abundant elements,

such as iron in copper ores, are usually uneconomic and discarded as waste.

Thermal-based separation is also impractical for pollution control and purification.

Of course, that’s why such problems are traditionally viewed as distinct

from resource extraction. Indeed, a number of embryonic molecular separation

technologies already exist whose development has largely been driven by addressing

purification issues.

Extracting solutions

In their simplest form, molecular separation techniques require that the material

being separated be free to flow as a gas or a liquid. Selectivity of the separation

is also fundamental: Usually only one particular dissolved species is of interest,

but it is dispersed in a background of many others. Sometimes the species is

valuable (for example, palladium and lithium), whereas in other cases it is

toxic (for example, lead and cadmium).

One particular set of approaches toward selective molecular separation has

been the focus of a tremendous amount of research in recent decades. Such efforts

involve molecules with branched and ring structures that can bind tightly and

specifically only with certain solutes. For instance, a group of organic molecules

called crown ethers are highly effective extraction agents for many metal ions.

Crown ethers are strongly selective. The ring, or “crown,” changes

in structure by substituting differently sized atoms, such as nitrogen and sulfur,

for oxygen in the crown. For example, the crown ether 18-crown-6 forms a strong

complex with the potassium ion, which fits nicely into the ring, whereas the

smaller ring of 12-crown-4 strongly binds with the lithium ion, but is too small

to accommodate potassium.

One application of such a separation system is to tether the extraction agent

to a substrate to form a highly selective surface for extracting particular

solutes from solution. For example, researchers have used a substituted crown

ether tethered to a silica surface to recover palladium from scrap catalytic

converters dissolved in acid. The palladium is bound, while the other much more

abundant metals remain in solution.

The major problem with such approaches to separation is that eventually the

solute must release its captured ions to regenerate the extraction agent. Typically

this takes extreme chemical measures. In the palladium recovery system, for

example, highly concentrated acid must be used to flush out the palladium.

Such steps generate a much larger volume of wastewater that now becomes a serious

disposal problem. Separation requiring washing with fluids can be practical

for recovery of highly valuable commodities like palladium, but its applications

are obviously limited.

So-called switchable binding provides a way to solve the problem: Under one

set of circumstances, binding occurs, but changing some variable causes the

solute to unbind again. Again, biology has anticipated technology. Hemoglobin,

for example, binds strongly to oxygen in the lungs, but under different chemical

conditions elsewhere in the body, it gives up the oxygen to the tissues.

An example of switchable binding is “electrosorption,” which is based

on straightforward principles of attraction and repulsion. Charging an electrode

attracts ions with the opposite charge; reversing the charge of the electrode

desorbs the ions again. Although first proposed in the 1960s for desalination,

electrosorption remained impractical until the recent advent of nanostructured

electrodes with very high surface areas. Because the “filled up” electrodes

look like a charged capacitor, too, a great deal of the electrical energy can

be recovered when the ions are desorbed.

More selective approaches require more molecular-scale structuring. For example,

researchers have patented a process for extracting lithium ion from brine that

uses electrodes made of a form of crystalline manganese dioxide. In the process,

the electrode becomes negative, which leaves the crystal with an overall negative

charge, so positive lithium cations are drawn into tunnels in the structure

to compensate. Lithium cations can fit into these tunnels, whereas larger cations

cannot. Reversing the charge on the manganese dioxide electrode then expels

the lithium.

A similar system for extracting cesium ion is based on cesium nickel hexacyanoferrate.

Here, the crystal structure contains large cavities that can accommodate the

big cesium ion. Again, on applying a negative voltage, cesium cations are drawn

in to compensate. The system is of great interest for extracting highly radioactive

cesium-137 from nuclear waste.

An alternative potential trigger for switching binding is light. One way is

to use molecules that change their structure upon absorbing a photon. The “backbone”

of spiropyrans, a specialized class of molecules, for example, rearranges so

drastically that a solution containing the molecule actually changes color when

illuminated. Strategically arranging the extracting groups on the backbone can

make the molecule go from binding solutes in its ground state to releasing them

upon illumination.

A different approach uses the absorption of light by a semiconductor surface,

but such systems are nascent. In this case, the photogenerated electric charge

would drive molecular mechanisms at the surface. For example, a surface might

adsorb ions from a solution in the dark, but desorb those ions when illuminated.

Merely shining sunlight on a surface to desorb its solutes would obviously be

much cleaner and “greener” than flushing it with strong acid solutions!

Blurring the lines

At present, pollution control and purification are the key economic drivers

for these separation technologies. As they mature, however, they will blur the

distinction between a “pollutant” and a “resource.” Moreover,

recovered pollutants will begin to have an impact on resource extraction. After

all, copper extracted from a wastewater stream is copper that does not have

to be mined.

Ultimately, a great many aqueous solutions, of both natural and artificial

origin, will become nontraditional resources. Wastewater streams, acid-mine

drainage, seawater, concentrated natural brines such as those in oilfields or

saline lakes — sometimes viewed now as problems — all could become

potential sources of materials with the help of nanotechnology.